Mobile welding is a dynamic field that demands versatility and preparedness for various tasks in the field. Ensuring your welding rig is well-equipped and optimized is vital for the success of your mobile welding business. Here, we’ll explore essential considerations for setting up your mobile welding truck and how to make the most of your equipment and technology, emphasizing the importance of “Mobile Welding.”

Setting Up Your Welding Rig

When configuring your welding truck for a field fabrication venture, several crucial questions will influence your choices regarding the truck and equipment:

Nature of Work:

Determine the type of work you’ll be handling. Will it primarily involve heavy equipment repairs, or will you also take on projects that require structural work with high-quality and non-destructive testing? The broader your range of jobs, the more versatile your equipment needs to be.

Required Processes:

Consider the welding processes you’ll need. If your work involves gouging, air tools, and various welding processes, choose a welder/generator that offers multi-process capabilities. Ensure it aligns with your business goals and future expansion plans.

Budgetary Constraints:

Assess your budget. Starting small and gradually upgrading your truck and equipment as your business grows is a valid strategy. Keep in mind potential additions like cranes or the capacity to haul equipment on a trailer, providing flexibility for diverse job requirements.

Selecting Equipment for Mobile Welding

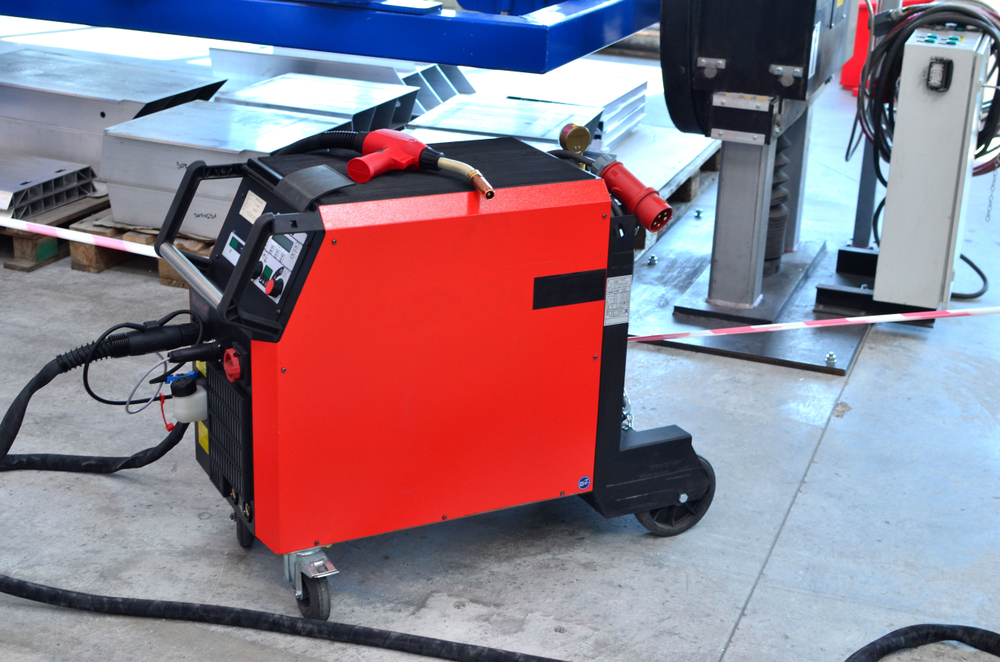

Three fundamental components are essential for your mobile welding truck: a welder, a generator, and an air compressor. These are indispensable for welding and carbon-arc gouging, common processes for field fabricators. Additionally, having a truck equipped with a crane can prove invaluable for moving heavy equipment and materials.

When choosing a work truck, opt for a heavy-duty vehicle rather than a half-ton truck to accommodate your equipment adequately. Plan ahead and select a truck that can adapt to the growing demands of your business, providing the space and weight capacity needed for additional tools and equipment.

Key Features and Additions for Efficiency

Investing in your mobile welding truck and welder/generator is a significant step in your business. To maximize your investment, consider key features and additions that streamline your operations and save you time and money:

Spools and Reels:

These additions facilitate the easy management of welding leads on the job site, a task frequently performed. They are particularly handy during adverse weather conditions.

Gas Racks or Double Racks:

Organize bottles for oxy-acetylene setups and shielding gases, minimizing clutter on your truck.

Filler Metal Storage:

Proper storage for filler metals prevents moisture absorption and contamination. Consider investing in field containers to store stick and TIG rods.

Battery Charge:

A welder/generator with battery charge and jump-start capabilities is crucial for heavy equipment maintenance and repair tasks.

Remote Solutions:

Welder/generators with remote solutions offer ease of access to the machine, reducing the need to climb in and out of the truck. They enhance convenience when accessing output panels, turning the machine on or off, or adjusting parameters.

Fuel-saving and Noise-reducing Technologies:

For frequent use of your welder/generator for repairs and powering jobsite tools, choose a machine with fuel-efficient and noise-reducing technologies. These advancements enhance operator comfort and productivity.

Wire Feeders:

Consider investing in wire feeders for efficient wire welding, which can save substantial time on large repair jobs compared to stick welding. If your machine features ArcReach® technology, an ArcReach-enabled feeder provides precise parameter control at the weld joint.

Optimizing Your Mobile Welding Rig

Your welding rig serves as the nucleus of your field fabrication business. Choosing dependable, versatile tools and equipment is pivotal for your success and your ability to undertake a variety of jobs. Explore the lineup of Miller solutions, renowned for their industry-leading technologies that enhance efficiency and cost-effectiveness, enabling you to thrive in the world of “Mobile Welding.”

Ensuring Safety on the Field:

Prioritize safety measures and equipment on your mobile welding rig to create a secure working environment for you and your team.

Regular Maintenance and Inspections:

Implement a routine maintenance schedule for your welding equipment to ensure optimal performance and longevity.

Staying Organized:

Efficiently organize your tools and supplies within your mobile welding truck for easy access and a clutter-free workspace.

Adapting to Environmental Conditions:

Consider weatherproofing your mobile welding rig to withstand various environmental challenges, including extreme temperatures and precipitation.

Training and Certification:

Invest in ongoing training and certification for yourself and your team to stay updated on the latest welding techniques and safety protocols.

Client Communication:

Develop effective communication strategies with clients to understand their project requirements and provide exceptional service.

Documentation and Record-keeping:

Maintain detailed records of your work, including project specifications, client communications, and equipment maintenance logs.

By addressing these additional aspects of mobile welding, you can further enhance the efficiency and success of your field fabrication business.